Lub tshuab pellet yog ib yam khoom siv rau compressing biomass pellet roj thiab pellet pub, ntawm cov menyuam siab yog nws cov khoom tseem ceeb thiab qhov tsis zoo. Vim nws hnyav ua hauj lwm thiab hnyav ua hauj lwm tej yam kev mob, txawm nrog high quality, hnav thiab tsim kua muag yog inevitable. Nyob rau hauv cov txheej txheem ntau lawm, kev noj cov siab rollers yog siab, yog li cov khoom siv thiab kev tsim cov txheej txheem ntawm lub siab rollers yog qhov tseem ceeb tshwj xeeb.

Kev soj ntsuam tsis tiav ntawm lub siab cov menyuam ntawm lub tshuab particle

Cov txheej txheem ntawm cov menyuam siab muaj xws li: txiav, forging, normalizing (annealing), ntxhib machining, quenching thiab tempering, semi precision machining, nto quenching, thiab precision machining. Ib pab neeg tshaj lij tau ua cov kev tshawb fawb txog kev hnav ntawm biomass pellet fuels rau kev tsim khoom thiab kev ua haujlwm, muab lub hauv paus theoretical rau kev xaiv cov khoom siv rau cov menyuam thiab cov txheej txheem kho cua sov. Cov hauv qab no yog cov kev tshawb fawb xaus thiab cov lus pom zoo:

dents thiab khawb tshwm nyob rau saum npoo ntawm lub siab cov menyuam ntawm lub granulator. Vim yog hnav ntawm tawv impurities xws li xuab zeb thiab hlau filings ntawm lub siab rau cov menyuam, nws belongs rau qhov txawv txav. Qhov nruab nrab ntawm qhov hnav yog li 3 hli, thiab hnav ntawm ob sab sib txawv. Cov khoom noj muaj hnyav hnyav, hnav ntawm 4.2mm. Feem ntau yog vim qhov tseeb tias tom qab pub mis, homogenizer tsis muaj sijhawm los faib cov khoom sib npaug thiab nkag mus rau txheej txheem extrusion.

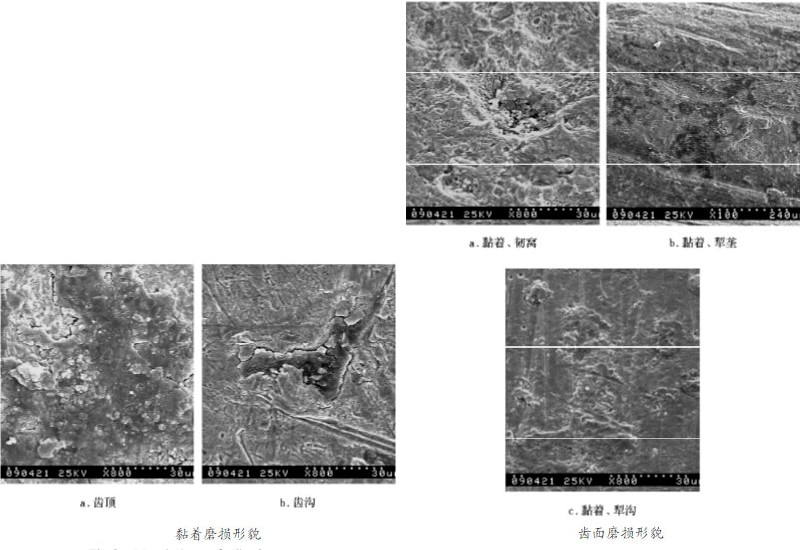

Microscopic hnav tsis ua hauj lwm tsom xam qhia tau hais tias vim lub axial hnav nyob rau saum npoo ntawm lub siab roller tshwm sim los ntawm raw cov ntaub ntawv, tsis muaj cov khoom nto ntawm lub siab roller yog lub ntsiab ua rau tsis ua hauj lwm. Cov ntaub ntawv tseem ceeb ntawm kev hnav yog adhesive hnav thiab abrasive hnav, nrog morphology xws li tawv pits, plow ridges, plow grooves, thiab lwm yam, qhia tau hais tias cov silicates, xuab zeb hais, hlau filings, thiab lwm yam nyob rau hauv cov ntaub ntawv raw muaj hnyav hnav nyob rau hauv lub siab ntawm cov menyuam. Vim yog qhov ua ntawm dej vapor thiab lwm yam, cov av nkos zoo li cov qauv tshwm sim rau ntawm qhov chaw ntawm lub siab cov menyuam, ua rau muaj kev ntxhov siab corrosion tawg rau ntawm qhov chaw siab ntawm cov menyuam.

Nws raug nquahu kom ntxiv cov txheej txheem tshem tawm impurity ua ntej crushing cov ntaub ntawv raw kom tshem tawm cov xuab zeb hais, hlau filings, thiab lwm yam impurities sib xyaw rau hauv cov ntaub ntawv raw, txhawm rau tiv thaiv qhov txawv txav thiab tsim kua muag ntawm lub siab rollers. Hloov cov duab lossis kev teeb tsa ntawm lub scraper kom sib npaug ntawm cov khoom siv hauv compression chamber, tiv thaiv tsis sib xws ntawm lub zog rau cov menyuam thiab ua rau hnyav hnyav rau ntawm qhov chaw ntawm cov menyuam siab. Vim yog qhov tseeb tias cov menyuam lub siab feem ntau ua tsis tiav vim qhov hnav, txhawm rau txhim kho nws qhov siab tawv, hnav tsis kam, thiab corrosion kuj, hnav-tiv taus cov ntaub ntawv thiab cov txheej txheem kho cua sov tsim nyog yuav tsum tau xaiv.

Cov khoom siv thiab txheej txheem kev kho mob siab rollers

Cov khoom muaj pes tsawg leeg thiab cov txheej txheem ntawm cov menyuam siab yog qhov yuav tsum tau ua ua ntej rau kev txiav txim siab nws hnav tsis kam. Cov khoom siv rau cov menyuam feem ntau suav nrog C50, 20CrMnTi, thiab GCr15. Cov txheej txheem tsim khoom siv CNC tshuab cuab yeej, thiab cov menyuam nto tuaj yeem kho nrog cov hniav ncaj, oblique hniav, drilling hom, thiab lwm yam raws li kev xav tau. Carburization quenching lossis high-frequency quenching tshav kub kho yog siv los txo cov menyuam deformation. Tom qab kev kho cua sov, precision machining yog ua dua los xyuas kom meej lub concentricity ntawm lub puab thiab txheej voj voog, uas yuav prolong lub neej kev pab cuam ntawm cov menyuam.

Qhov tseem ceeb ntawm kev kho cua sov rau lub siab rollers

Kev ua haujlwm ntawm cov menyuam lub siab yuav tsum ua kom tau raws li qhov yuav tsum tau muaj ntawm lub zog siab, siab hardness (hnav tsis kam), thiab siab toughness, nrog rau kev ua haujlwm zoo (xws li polishing zoo) thiab corrosion kuj. Thaum tshav kub kub kev kho mob ntawm siab rollers yog ib qho tseem ceeb txheej txheem ntawm unleashing lub peev xwm ntawm cov ntaub ntawv thiab txhim kho lawv cov kev ua tau zoo. Nws muaj kev cuam tshuam ncaj qha rau kev tsim khoom raug, lub zog, kev pabcuam lub neej, thiab cov nqi tsim khoom.

Rau tib cov ntaub ntawv, cov ntaub ntawv uas tau dhau los ntawm kev kho cua sov muaj ntau dua lub zog, hardness, thiab durability piv rau cov ntaub ntawv uas tsis tau overheating kev kho mob. Yog tias tsis quenched, lub neej kev pab cuam ntawm lub siab roller yuav luv dua.

Yog tias koj xav paub qhov txawv ntawm cov khoom siv hluav taws xob thiab cov khoom tsis muaj cua sov uas tau dhau los ua qhov tseeb, nws yog qhov tsis yooj yim sua kom paub qhov txawv ntawm lawv los ntawm hardness thiab kub kho oxidation xim. Yog tias koj tsis xav txiav thiab sim, koj tuaj yeem sim paub qhov txawv ntawm tapping suab. Cov qauv metallographic thiab kev sib txhuam sab hauv ntawm castings thiab quenched thiab tempered workpieces yog txawv, thiab muaj peev xwm txawv los ntawm maj mam tapping.

Lub hardness ntawm kev kho cua sov yog txiav txim los ntawm ntau yam, nrog rau cov khoom qib, qhov loj me, workpiece hnyav, zoo li tus qauv, thiab cov txheej txheem tom ntej. Piv txwv li, thaum siv lub caij nplooj ntoos hlav hlau los ua qhov loj, vim qhov tseeb thickness ntawm workpiece, phau ntawv qhia hais tias lub tshav kub kho hardness tuaj yeem ncav cuag 58-60HRC, uas tsis tuaj yeem ua tiav nrog cov khoom siv tiag tiag. Tsis tas li ntawd, qhov ntsuas tsis tsim nyog ntawm hardness, xws li hardness ntau dhau, tuaj yeem ua rau poob ntawm lub zog ntawm lub workpiece thiab ua rau tawg thaum siv.

Kev kho cua sov yuav tsum tsis tsuas yog ua kom muaj txiaj ntsig zoo ntawm hardness tus nqi, tab sis kuj ua tib zoo saib xyuas nws cov txheej txheem kev xaiv thiab kev tswj cov txheej txheem. Overheated quenching thiab tempering tuaj yeem ua tiav qhov xav tau hardness; Ib yam li ntawd, nyob rau hauv cua sov thaum lub sij hawm quenching, kho lub tempering kub kuj yuav ua tau raws li qhov yuav tsum tau hardness ntau yam.

Lub Baoke siab cov menyuam yog ua los ntawm cov hlau zoo C50, kom ntseeg tau qhov hardness thiab hnav tsis kam ntawm particle tshuab siab cov menyuam los ntawm qhov chaw. Ua ke nrog exquisite high-temperature quenching tshav kub kho tshuab, nws zoo heev expands nws cov kev pab cuam lub neej.

Post lub sij hawm: Jun-17-2024